Flat Glass

Survey

Delivery time: 1 week

Price: on request

Introduction

Among the various variants offered by the glass industry, flat glass has made a special place for itself. Flat glass covers a wide variety of products including float glass, sheet glass, figured and wired glass and polished plate glass, among others. The superior quality and distortion free nature of float glass makes it the most preferred glass over other forms of flat glasses. Float glass is extremely clear with light transmission up to 90%.

Flat Glass products are:

- Construction

- Automotive

- Solar

- Other & Special

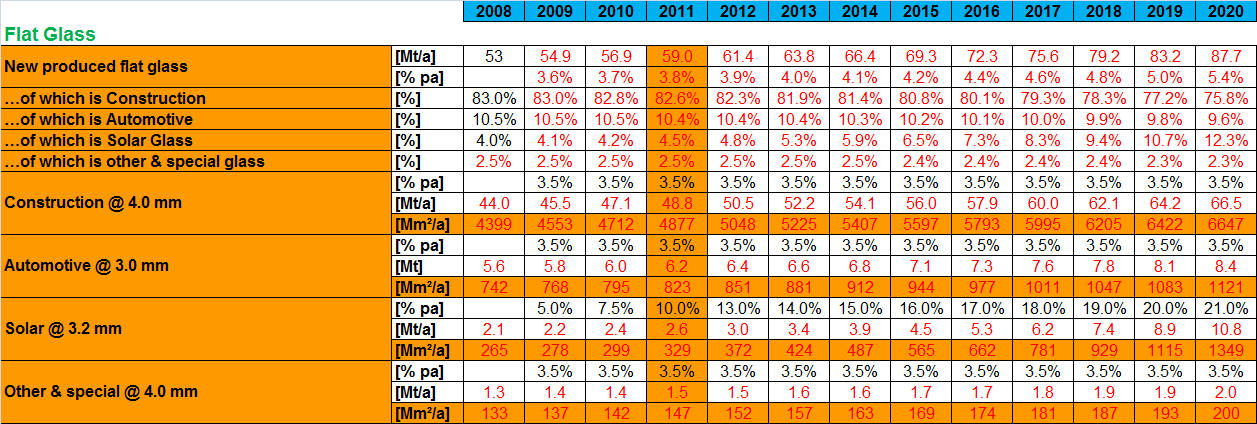

whereas glass for Construction purposes counts for more than 80% as shown in the following chart

Chart: Flat Glass market growth

Typically, there are three methods to manufacture basic glass from which all processed glass products are made:

Float

More than 85% of the global flat glass production is carried out through the float process. It is the most preferred way of making the high quality, optically clear glass.

Between 1953 and 1957, (Sir) Alastair Pilkington and Kenneth Bickerstaff

invented the Float Glass Process, a revolutionary method of high quality

flat glass production by floating molten glass over a bath of molten

tin, avoiding the costly need to grind and polish plate glass to make

it clear.

Pilkington then allowed the Float Process to be used under licence by

numerous manufacturers around the world.

Sheet

The sheet process of flat glass manufacturing represents 8-10% of the global production of flat glass. This process predates, competes with and is gradually being replaced by float.

Rolled

The rolling process is used to manufacture patterned, figured and wired glass products. Semi-molten glass is squeezed between metal rollers to produce a ribbon with controlled thickness and surface pattern.