Oxygen Enhanced Combustion (OxyFuel)

Motivation for using oxygen

Glass manufacturers are constantly under pressure to enhance production, improve quality and meet increasingly strict emission regulations. To overcome these challenges, they are looking for new ways to increase the pull rate, improve product quality and, in some instances, extend furnace life (to combat or prevent regenerator plugging).

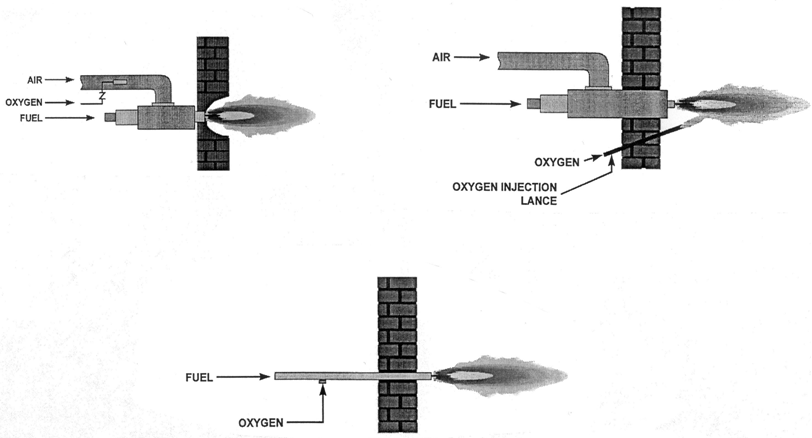

Oxygen has for many years been successfully used in the glass industry. Different technologies are available to suit individual furnace and process conditions:

- Oxygen enrichment

- Oxygen lancing

- Oxy-fuel boosting

- All oxy-fuel

Figure 1: Oxygen technologies

All of these processes are based, more or less, on the replacement of air with oxygen. Thanks to the elimination of nitrogen and the higher concentration of oxygen, they increase the flame temperature. They also improve the effectiveness of the gas jet due to the higher concentrations of CO2 and H2O in the vicinity of the flame. These gases are mainly responsible for thermal radiation.

Oxygen enrichment

Enrichment is the most basic form of using oxygen in glass melting applications. Enrichment is typically used in a furnace nearing the end of its campaign that is suffering from regenerator plugging or collapse.

Oxygen lancing

Oxygen lancing is used similarly to enrichment, but is typically associated with more severe or complex conditions. Lancing is the precise injection of oxygen to the point where it is most needed. Whilst enrichment is indiscriminate in its injection and is less efficient, more total oxygen may be injected through lancing.

Oxygen boosting (“Oxy Boosting”)

The difference between boosting and enrichment/lancing is that, in addition to the injection of oxidant, there is also the addition of fuel. Whilst boosting technologies can be used for recovery and furnace life extension, they also seek to increase the furnace throughput and/or improve quality.

The following technologies are examples of boosting.

- Hot spot boosting

- Conventional (horizontal) zero port boost technology

- CGM™ (vertical) Boost Technology

Chart 2 shows a flame view of a vertical crown burner, CGM™.

Figure 2: CGM™ flame view

All oxy-fuel fired melting (“All Oxy Fuel” or “AOF”)

One of the most popular oxygen applications, all oxy-fuel-fired melting eliminates the need for a combustion air or heat-recovery device. This process is one of the most efficient ways of reducing nitrogen oxides (NOx) and particulate emissions from glass furnaces.

Figure 3: Energy consumption of air fuel and oxy fuel installations as a function of the flue gas and air preheating temperatures

Chart 3 shows the energy consumption of different air fuel and oxy fuel installations as a function of the flue gas and air preheating temperatures i.e. a furnace with a flue gas temperature of 1480 °C and an air preheating temperature of 1000 °C saves 65% (100-35) of the energy compared to a furnace with no air preheating. When this furnace would be converted to AOF we can count with another 9% (35-26) compared to the furnace with no air preheating or 26% compared with the case of air preheating of 1000 °C.

The benefits of using oxygen within AOF are in particular:

- Reduced emissions with very low NOx and particulate emissions

- Improved heat transfer with enhanced glass quality

- Lower capital costs, no air preheating necessary, smaller filter unit, smaller furnace

- Increased productivity

- Better control over operations, smaller variations

- Replacement of missing combustion air

- Energy savings

Burner technology

Customers can choose from a big variety of burners. Principally all these burners are based on the principle, that fuel is shielded (conical) with oxygen, so called ‘tube-in-tube’. Changing the velocities of each partners allows to adapt the flame shape to the furnace and melting requirements.

When needed oxygen can be partly injected separately, staging, to increase the flame lengths.

GGC have many experience using oxygen for many purposes.